Introduction

The lathe stands as one of the oldest machine tools and earns the title "mother of machine tools" because it serves as the foundation for all other machine tools. Operators can perform a variety of cutting operations on a lathe, with or without additional attachments. The lathe rotates the workpiece while moving the cutting tool in a straight line. Manufacturers classify lathe machines based on their speed and application. In this blog, we will explore the classification, components, and functions of the lathe in detail.

Classification of Lathes

- Bench Lathe: This small lathe mounts on a separate table and includes all the attachments found on larger lathes. Operators use it to perform precise work.

- Speed Lathe: This lathe may come as a bench type or one supported by legs. It lacks a gearbox, carriage, and lead screw, so the operator moves and feeds the tool by hand. People use this lathe for wood turning, polishing, and spinning.

- Engine Lathe: This lathe remains the most widely used type. During the lathe’s early development, steam engines powered it, which is why people call it an engine lathe. Today, manufacturers equip engine lathes with separate engines or electric motors. Operators achieve various speeds by using cone pulleys and gears.

- Tool Room Lathe: This lathe closely resembles an engine lathe but includes extra attachments for more accurate and precise work. Common attachments include taper turning devices, follower rests, collets, and chucks.

- Capstan and Turret Lathes: These semi-automatic lathes perform a wide range of operations. They hold many more cutting tools than an engine lathe.

Functions and Components of a Lathe

- Bed: Supports all major components.

- Headstock: Holds the jaws for the workpiece,supplies power to the jaws and has various drive speed.

- Tailstock: Support the other end of the workpiece.

- Carriage: Slides along the ways and consists of the cross-slide,tool post,apron.

- Cross Slide: The operator mounts the cross slide on the carriage. It moves the cutting tool 90° to the workpiece.

- Apron: The apron contains the control and the gear that allow you to move the carriage and cross slide.

- Tool Post: The tool post support and secure the cutting tool or tool holder.

Importance in Modern Manufacturing

- Precision Machining: Lathes produce highly accurate and symmetrical parts, making them indispensable in industries that require precision.

- Versatility: From simple operations like turning and facing to more complex tasks like threading and profiling, lathes can handle a wide range of machining operations.

- Customization: Modern CNC (Computer Numerical Control) lathes have revolutionized customization, allowing manufacturers to create unique and complex components with ease.

- Mass Production: Lathes are also essential for mass production, enabling the rapid and consistent production of standardized components.

- Education and Training: Lathes play a significant role in training future machinists and engineers, helping them understand the fundamentals of machining.

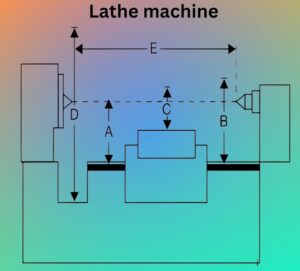

Specifications of Lathe

- Height of centre over bed (A).

- Maximum swing over bed (B).

- Maximum swing over carriage (C).

- Maximum swing in gap (D).

- Maximum length of work (E).

Constructional Detail of Lathe

Tail Stock: The tail stock supports the job at the end and slides along the bed. It may hold a dead center or a live center to provide point support, depending on the requirement. Figure 3 shows a tail stock. For tapping, drilling, or boring, the operator replaces the dead center with a tap or drill/boring tool. The operator moves the dead center forward or backward by manually rotating the hand wheel on the sleeve.

Carriage and Tool Post: It provides support to the tool post, cross slide, compound rest, apron, etc. The function of tool post is to hold cutting tool rigidly; tool post moves in both axial and transverse directions on compound rest. The function of swivel plate is to give angular direction to the tool post whereas the function of cross slide is to give the linear motion to the tool by rotating the attached hand wheel. Apron is a hanging part in front of the carriage. It is housing of gear trains and clutches. It gives automatic forward and reverse motion to the tool.

Legs: The legs provide rigid support to the entire machine tool. Operators firmly secure both legs to the floor using foundation bolts to prevent vibrations.

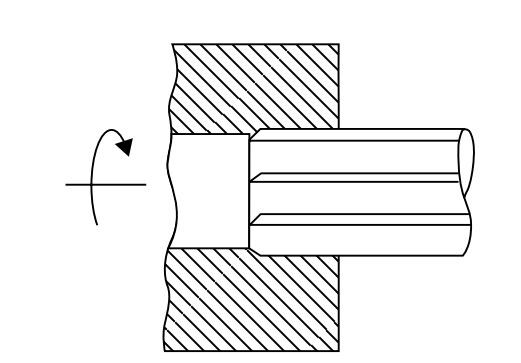

Chucks: The chuck holds the job securely. It may have three or four jaws, as shown in Figure 4. In a three-jaw chuck, all jaws move inward or outward simultaneously, making centering easy—this is why people also call it a universal chuck. In contrast, each jaw in a four-jaw chuck moves independently. This design can hold irregularly shaped jobs but requires manual centering. Operators also use magnetic chucks, which hold the job using the principle of electromagnetism.

Let driver shaft rotates at the speed of N rotation per minute (rpm) and the stepped diameters of the pulley are `D_1`,`D_2`,`D_3` and `D_4`.Driven shaft has pulley of same steps diameters but in

reverse order as shown in Figure 5. We know the speed is inversely proportional to the diameter, therefore,

All Geared Head Drive

Cutting Tools Used in Lathe

A number of cutting operations are performed on a lathe machine. Therefore, various cutting tools are used in lathe such as left-hand and right-hand turning tools, facing tools, threading tools, parting-off tool, etc., as shown in Figure 7.

Types of Operations on Lathe Machine

Turning

Straight Turning

Shoulder Turning

Eccentric Turning

Taper Turning

- Taper turning by swivelling compound rest: Job rotates on lathe axis and tool moves on angular path. It can be applied from any angle `0^circ`-`90^circ` for short length of taper up to 150 mm (approximate) `tanleft(alpharight)`=`frac{D_1-D_S}{2l}`.It is used for shorter length and steeper angle. Here,`D_1` and `D_S` are larger and shorter diameters, l is length of the job, and is angle of taper.

- Taper turning by off-setting the tailstock: Job rotates at an angle to the lathe axis and the tool travels longitudinally to the lathe axis. Any angle 0° – 8°, long job of smaller diameter can be turned by this method. It is also used for internal taper turning.

- Taper turning attachment: Job rotates on lathe axis and tool moves in guided angular path. Long jobs of steeper angle of taper (0° – 12°) can be done by this attachment. Guide rail is set as per angle of taper. It is applied for mass production.

- Taper tuning by a form tool: Job rotates on lathe axis and tool moves crosswise direction,perpendicular to the lathe axis. Very small length of taper and any angle 0° – 90°.Tool itself designed as per requirements. It is used for mass production for Chamfering on bolts, nuts, bushes, etc.

- Taper turning by combination fed: Job rotates on lathe axis and tool travels on resultant path, for any length and any angle. Taper angle is to be determined by trial and error method.It is applied by hand feeds by combined feeding of tool (axial and perpendicular) for taper turning.

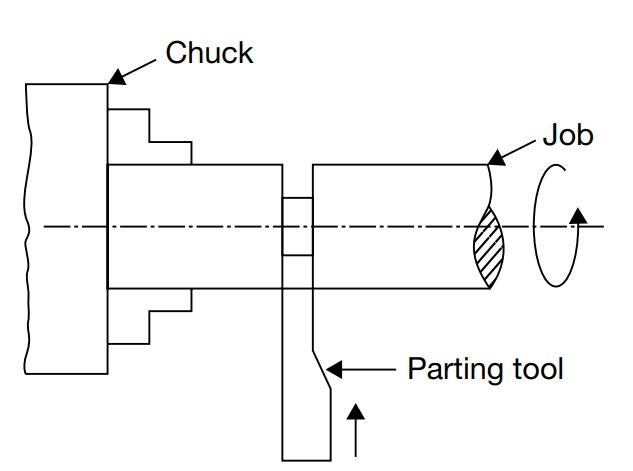

Parting-off (Grooving)

Knurling

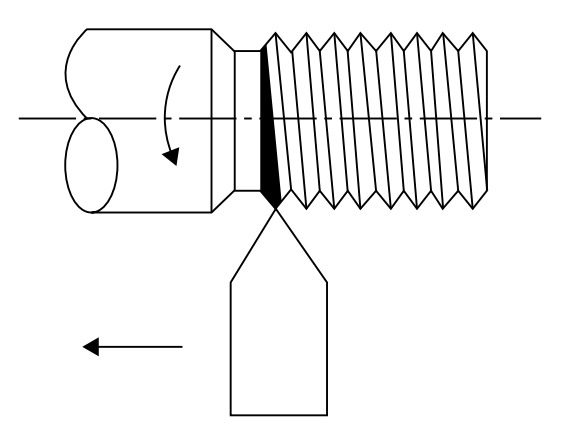

- Hold the job on machine and turn up to major diameter of the thread.

- Choose suitable thread cutting tool.

- Select slower speed of the lathe spindle.

- Calculate the change gear ratio based on the following formula:

Change gear ratio=pitch of the job×No. of startPitch of the lead screw

- Fix the calculated change gear ratio to the head stock spindle, intermediate shaft, and lead screw shaft.

- Choose suitable depth of cut. Three or four cuts are necessary to complete the thread.

- Arrange job and tool proper position and give desired depth of cut.

- Engage half nut with respect to chasing dial according to odd/even threads.

- Allow the movement of the tool up to the portions of the job necessary for thread cutting

then lifting the tool from the job. - Disengage the half nut, move the carriage to the right side up to the position from where

second cut will start. Allowing the second depth of cut again engages the half nut with

respect to chasing dial.

Drilling

Generally, drilling forms a circular hole by rotating the tool. However, in a lathe, the drill remains static, and the job rotates via the tailstock feed. Consequently, metal is removed through shearing and extrusion. In most cases, holes become slightly oversized because of misalignment or vibration. Therefore, an undersized drill is preferred. Subsequently, in addition, reaming or boring ensures accuracy. Furthermore, alignment boosts precision. Nevertheless, improper setup causes defects. On the other hand, careful setup prevents issues. In contrast, poor setup affects hole shape. Moreover, choosing the right bit is essential. In other words, each step impacts accuracy. As a result, holes meet required standards. Besides, vibration control is crucial. Likewise, rigid setup helps. To clarify, drill depth must match the hole. Also, proper lubrication aids performance. Eventually, the drill reaches final depth, as shown in Figure 16. Ultimately, accuracy depends on the entire process.

Drilling on a lathe is a straightforward process. The operator holds the drill bit in the tailstock, replacing the dead center, and moves it forward while applying pressure to the end of the rotating job.

Tapping

Reaming

Boring

Spinning

Conclusion

The lathe machine is not as simple as it was and it is today a complex machine that helps produce various produces. It is not surprising that it is a foundation of industries, in a wide field of application such as aerospace and automotive, electronic technologies of medicine, electronics and healthcare. The skilled hands of the lathe operators mold the world and propel, innovation still serves as a testimony of the multifaceted importance skill and technology has brought to human society.