Introduction

For centuries, humans have used stones in countless ways, from building ancient monuments to shaping modern infrastructure. This section explores the world of stones—examining their types, testing methods, characteristics, and diverse applications.

Tests on Stones

- crushing strength test

- water absorption test

- abrasion test

- impact test

- acid test

1.Crushing Strength Test: To conduct this test, prepare specimens of size 40 × 40 × 40 mm from the parent stone. Dress the sides finely and immerse the specimens in water for 3 days. After saturation, apply a layer of plaster of Paris to the top and bottom surfaces to create even contact areas for uniform load distribution. Alternatively, you can use a pair of 5 mm thick plywood sheets instead of plaster of Paris to achieve the same effect.

Place the specimen in the compression testing machine and apply the load at a rate of 14 N/mm² per minute. Record the crushing load when failure occurs. Calculate the crushing strength by dividing the crushing load by the area over which you applied the load. Test at least three specimens and take the average value as the final crushing strength.

2.Water Absorption Test: Prepare cube specimens weighing about 50 grams each and carry out the test by following the steps given below:

- Note the weight of dry speciment as `W_1`.

- Place the specimen in water for 24 hours.

- Take out the specimen, wipe out the surface with a piece of cloth and weigh the specimen. Let its weight be `W_2`.

- Suspend the specimen freely in water and weight it. Let its weight be `W_3`.

- Place the specimen in boiling water for 5 hours. Then take it out, wipe the surface with cloth and weigh it. Let this weight be `W_4`.Then,

Percentage absorption by weight = `frac{W_2-W_1}{W_1}` × 100 .....(1)

- Los Angeles abrasion test

- Deval abrasion test

- Dorry’s abrasion test.

Engineers prefer the Los Angeles abrasion test because its results correlate well with pavement performance.

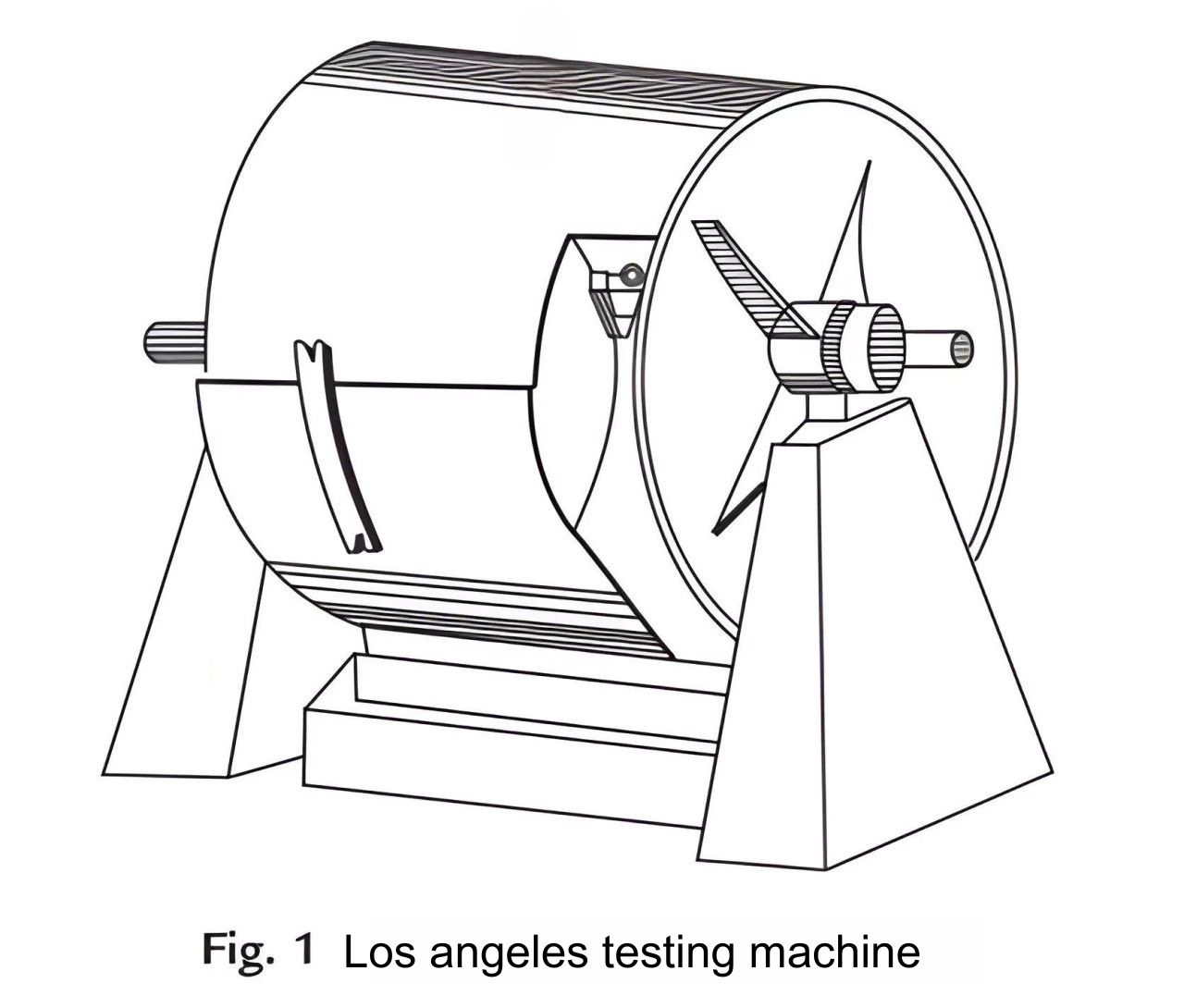

The Los Angeles apparatus [Fig. 1] includes a hollow cylinder with an inside diameter of 0.7 m and a length of 0.5 m, sealed at both ends. Technicians mount it on a frame that allows rotation around a horizontal axis. The IS code specifies the test procedure for various specimen gradations. During testing, they place a specified weight of the specimen and a designated number of 48 mm diameter cast iron balls inside the cylinder.

The operator rotates the cylinder at a speed of 30 to 33 rpm for a specified number of revolutions (500 to 1000). After rotation, they remove the aggregate and sieve it using a 1.7 mm IS sieve. They then weigh the material that passes through the sieve and calculate the Los Angeles value accordingly.

[Weight of aggregate passing through sieve Original Weight × 100]

The following values are recommended for road works:

4.Impact Test: The resistance of stones to impact is determined by conducting impact tests using a standardized impact testing machine (as shown in Fig. 2). It consists of a frame with guides in which a metal hammer weighing 13.5 to 15 kg can freely fall from a height of 380 mm.

The technician fills aggregates of size 10 mm to 12.5 mm into the cylinder in three equal layers, tamping each layer 25 times. They then transfer the same material to the cup and tamp it 25 more times. Next, they allow the hammer to fall freely on the specimen 15 times. Finally, they sieve the specimen using a 2.36 mm sieve. Then,

The recommended impact values for various works are:

- for wearing course > 30%

- for bituminous mechadam > 35%

- for water bound mechadam > 40%

Common Building Stones

- Basalt and trap

- Granite

- Sand stone

- Slate

- Laterite

- Marble

- Gneiss

- Quartzite

- Basalt and Trap: These igneous stones have a medium to fine-grained, compact structure. Their color ranges from dark gray to black. Fractures and joints commonly occur in them. Their weight ranges from 18 kN/m³ to 29 kN/m³, and their compressive strength ranges from 200 to 350 N/mm². Builders use them as road metals, concrete aggregates, and in rubble masonry works for bridge piers, river walls, and dams. They also use them as pavement material.

- Granite: Granites belong to the igneous rock category. Their color ranges from light gray to pink, and they have a crystalline structure that varies from fine to coarse grain. They take polish well and remain hard and durable. Their specific gravity ranges from 2.6 to 2.7, and their compressive strength falls between 100 and 250 N/mm². Builders primarily use granites for bridge piers, river walls, and dams. They also use them for kerbs and pedestals. Granite commonly appears in monumental and institutional buildings. People use polished granite for table tops, column cladding, and wall finishes. Construction teams also use granite as coarse aggregates in concrete.

- Sand stone: These stones are sedimentary and therefore stratified in nature. They contain quartz and feldspar and occur in various colors such as white, grey, red, buff, brown, yellow, and even dark gray. Their specific gravity ranges from 1.85 to 2.7, and their compressive strength varies between 20 and 170 N/mm². Their porosity lies between 5 and 25 percent. When exposed to weathering, these stones become unsuitable for construction. Engineers prefer to use sandstones with silica cement in heavy structures when needed. Builders commonly use them for masonry work, dams, bridge piers, and river walls.

- Slate: These metamorphic stones consist of quartz, mica, and clay elements. They have a fine-grained structure and can fracture readily along the original bedding planes. Their colours range from dark gray and greenish gray to purple gray and black. Roofing tiles, slabs, and pavements usually employ these materials, which have a specific gravity of 2.6 to 2.7 and compressive strength of 100 to 200 N/mm².

- Laterite: It is a metamorphic stone. It is having porous and sponges structure. It contains high percentage of iron oxide. Its colour may be brownish, red, yellow, brown and grey. Its specific gravity is 1.85 and compressive strength varies from 1.9 to 2.3 N/`mm^2`. It can be easily quarried in blocks. Seasoning increases its strength. When used as a building stone, builders should plaster its outer surface to protect it from weathering.

- Marble: This is a metamorphic stone. It can take good polish. It is available in different pleasing colours like white and pink. Its specific gravity is 2.65 and compressive strength is 70–75 N/`mm^2`. It is used for facing and ornamental works. It is used for columns, flooring, steps etc.

- Gneiss: It is a metamorphic stone. It is having fine to coarse grains. Alternative dark and white bands are common. Light grey, pink, purple, greenish gray and dark grey coloured varieties are available. These stones are not preferred because of deleterious constituents present in it. They may be used in minor constructions. However hard varieties may be used for buildings.The specific gravity varies from 2.5 to 3.0 and crushing strength varies from 50 to 200 N/`mm^2`.

- Quartzite: Quartzites are metamorphic stone. The structure is fine to coarse grained and often granular and branded. They are available in different colours like white, gray, yellowish. Quartz is the chief constituent with feldspar and mica in small quantities. The specific gravity varies from 2.55 to 2.65. Crushing strength varies from 50 to 300 N/`mm^2`. They are used as building blocks and slabs. They are also used as aggregates for concrete.

Type of Stones

Stones used for civil engineering works may be classified in the following three ways:

- Geological

- Physical

- Chemical

Geological Classification

Based on their origin of formation stones are classified into three main groups—Igneous, sedimentary and metamorphic stone.

1.Igneous stone: These stone are formed by cooling and solidifying of the stone masses from their molten magmatic condition of the material of the earth. Generally igneous stone are strong and durable. Granite, trap and basalt are the stone belonging to this category, Granites are formed by slow cooling of the lava under thick cover on the top. Hence they have crystalline surface. The cooling of lava at the top surface of earth results into non-crystalline and glassy texture. Trap and basalt belong to this category.

2.Sedimentary stone: Due to weathering action of water, wind and frost existing stone disintegrates. The disintegrated material is carried by wind and water; the water being most powerful medium. Flowing water deposits its suspended materials at some points of obstacles to its flow. These deposited layers of materials get consolidated under pressure and by heat. Chemical agents also contribute to the cementing of the deposits. The stone thus formed are more uniform, fine grained and compact in their nature. They represent a bedded or stratified structure in general. Sand stones, lime stones, mud stones etc. belong to this class of stone.

3.Metamorphic stone: Previously formed igneous and sedimentary stone under go changes due to metamorphic action of pressure and internal heat. For example due to metamorphic action granite becomes greisses, trap and basalt change to schist and laterite, lime stone changes to marble, sand stone becomes quartzite and mud stone becomes slate.

Physical Classification

Based on the structure, the stone may be classified as:

- Stratified stone

- Unstratified stone

- Foliated stone

1.Stratified stone: These stone are having layered structure. They possess planes of stratification or cleavage. They can be easily split along these planes. Sand stones, lime stones, slate etc. are the examples of this class of stones.

2.Unstratified stone: These stone are not stratified. They possess crystalline and compact grains. They cannot be split into thin slab. Granite, trap, marble etc. are the examples of this type of stone.

3.Foliated stone: These stone have a tendency to split along a definite direction only. The direction need not be parallel to each other as in case of stratified stone. This type of structure is very common in case of metamorphic stone.

Chemical Classification

On the basis of their chemical composition engineers prefer to classify stone as:

- Silicious stone

- Argillaceous stone

- Calcareous stone

1.Silicious stone: The main content of these stone is silica. They are hard and durable. Examples of such stone are granite, trap, sand stones etc.

2.Argillaceous stone: The main constituent of these stone is argil i.e., clay. These stones are hard and durable but they are brittle. They cannot withstand shock. Slates and laterites are examples of this type of stone.

3.Calcareous stone: The main constituent of these stone is calcium carbonate. Limestone is a calcareous stone of sedimentary origin while marble is a calcareous stone of metamorphic origin.

Properties of Stones

The following properties of the stones should be looked into before selecting them for engineering works:

1.Structure:Stone can have either a stratified (layered) or unstratified structure. Workers can easily dress stratified stones, making them suitable for superstructures. Unstratified stones, being harder and more difficult to dress, serve better in foundation works.

2.Texture: Fine grained stones with homogeneous distribution look attractive and hence they are used for carving. Such stones are usually strong and durable.

3.Density: Denser stones are stronger. Light weight stones are weak. Hence stones with specific gravity less than 2.4 are considered unsuitable for buildings.

4.Appearance: A stone with uniform and attractive colour is durable, if grains are compact. Marble and granite get very good appearance, when polished. Hence they are used for face works in buildings.

5.Strength: Strength is an important property to be looked into before selecting stone as building block. Indian standard code recommends, a minimum crushing strength of 3.5 N/`mm^2` for any building block. Here we shows the crushing strength of various stones. Due to non-uniformity of the material, usually a factor of safety of 10 is used to find the permissible stress in a stone. Hence even laterite can be used safely for a single storey building, because in such structures expected load can hardly give a stress of 0.15 N/`mm^2` . However in stone masonry buildings care should be taken to check the stresses when the beams (Concentrated Loads) are placed on laterite wall.

6.Hardness:Hardness plays an important role when engineers use stone for flooring and pavement. They determine the coefficient of hardness by testing a standard specimen in Dory’s testing machine. For road works, the coefficient of hardness must be at least 17. Builders should avoid using stones with a coefficient below 14 for building works.

7.Percentage wear: Engineers measure it using the attrition test, an important property to consider when selecting aggregate for road works and railway ballast. A good stone should not show wear of more than 2%.

8.Porosity and Absorption: All stones have pores and hence absorb water. The reaction of water with material of stone cause disintegration. The absorption test measures the percentage of water a stone absorbs after immersing it in water for 24 hours.For a good stone it should be as small as possible and in no case more than 5.

9.Weathering: Rain and wind cause loss of good appearance of stones. Hence stones with good weather resistance should be used for face works.

10.Toughness:Toughness refers to the resistance to impact. Engineers determine it through an impact test. They prefer stones with a toughness index greater than 19 for road works. Stones with an index between 13 and 19 fall into the medium toughness category, while those with an index below 13 qualify as poor-quality stones.

11.Resistance to Fire: Sand stones resist fire better. Argillaceous materials, though poor in strength, are good in resisting fire.

12.Ease in Dressing:The cost of dressing significantly contributes to the overall cost of stone masonry. Stones with lower strength are easier to dress. Therefore, an engineer should prioritize sufficient strength over high strength when selecting stones for building works.

13.Seasoning: The stones obtained from quarry contain moisture in the pores. Seasoning removes moisture from the pores of stone and improves its strength before use.The best way of seasoning is to allow it to the action of nature for 6 to 12 months. This is very much required in the case of laterite stones.

The following is the list of uses of stone:

- Builders use stone masonry to construct foundations, walls, columns, and arches in a building.

- Builders use stones as flooring materials. They often choose marble, known for its attractive appearance, for flooring in luxurious buildings.

- Builders use stone slabs as damp proof courses, lintels, and sometimes even as roofing material.

- Builders use stones with good appearance for the face works of buildings. They commonly use polished marble and granite for this purpose.

- Builders use stones to pave roads, footpaths, and open spaces around buildings.

- Workers mix crushed stones with murram to create the base course for roads. They combine very small stone pieces with tar to form the finishing coat of roads.

- Crushed stones are used As a basic inert material (jelly/coarse aggregate) in concrete,As railway ballast,For making artificial stones and hollow building blocks.

- In addition, engineers also use stones to construct piers and abutments of bridges. This is primarily because stone offers excellent durability and strong resistance to water and weathering. Furthermore, it performs well under harsh environmental conditions, which makes it ideal for such critical structures. As a result, engineers continue to select stone for specific structural applications where long-term performance is essential. Despite this, the rise of modern alternatives such as reinforced concrete and steel has limited its use in many contemporary projects. Nevertheless, stone remains a valuable and time-tested material, particularly in projects requiring both strength and aesthetic appeal.

- Builders commonly use stone as a basic construction material in buildings, retaining walls, and dams. However, the popularity of stone as a building material has declined over time, mainly due to the following reasons. To begin with, the high transportation costs make it less economical. In addition, the labor-intensive nature of stone installation increases both time and expense. Moreover, the widespread availability of cheaper and easier-to-use alternatives has further reduced its appeal. Consequently, builders are more inclined to choose materials that are not only cost-effective but also easier to work with. Therefore, in modern construction practices, stone is often replaced by materials that offer greater efficiency, uniformity, and convenience. Nevertheless, stone still holds value in certain specialized or aesthetic applications.

- Availability of stones within a reasonable distance from the cities is becoming scare. As a result, the cost of stone at construction sites in cities is increasing. This rise, in turn, can be attributed to factors such as transportation challenges, limited availability, and growing demand. Consequently, project budgets may need to be adjusted to accommodate the higher material expenses.

- Labour cost for handling and dressing of stones is high.

- As the surfaces of stones are not uniform, mortar consumed in stone masonry is high.

- Mortar bricks and hollow concrete blocks which are easy to handle and consume less mortar are becoming more popular.

- Engineers consider R.C.C. and steel more dependable than stone, primarily because these materials offer uniform strength.As a result, designers tend to prefer them for all important and large-scale buildings. In fact, their consistent quality ensures structural reliability and safety. Moreover, their predictable performance, combined with ease of construction and adaptability, makes them ideal choices in modern structural design. Consequently, these materials have become the standard in contemporary architecture and engineering projects. Nonetheless, builders still use stone for decorative or specialized purposes where they value visual appeal and tradition.

Conclusion

Ultimately, stones are more than just lifeless substances; rather, they are extraordinary geological wonders with distinct features and a deep past. By exploring the variety of stones, methods of analysis, qualities, and uses, we are better able to maximize their usefulness in constructing lasting buildings and timeless artistic creations. Even though technology has significantly advanced, stones still persist as a fundamental and dependable element in the advancement of humanity. In fact, their enduring presence highlights not only their physical strength but also their cultural and historical significance. Therefore, understanding and appreciating stones is essential to both modern innovation and the preservation of tradition.